Chemical Free Floor Stripping Orbital Machines For VCT Vinyl Composite Tile

First things first, what is vinyl composite tile, AKA VCT?

VCT is made from a composite material that is aimed at creating a tile that is made of a minimized amount of vinyl in combination with limestone and other materials. The goal is to go with a more cost-effective material that still looks the part.

VCT in its original state has little slip resistance. It is relatively soft and highly porous, so that dirt, grease, and water will quickly penetrate surface, making the floor either slick or sticky – and hazardous.

When you walk, friction helps hold your foot in place as your foot presses against the floor to move you forward.

To imagine walking without friction, think of walking on ice. The slick ice provides little friction and your foot slides when you try to walk. Too little friction will cause your foot to slip. Too much friction will stop your foot mid-stride and cause you to trip.

So is that why we apply a floor finish or wax?

Yes but atheistically there are other reasons why floor finish and wax is applied to VCT. Floor finished and waxes provide a durable, slip-resistant surface for easy walking.

Floor wax protects the floor itself. VCT is composed of a small amount of vinyl synthesized with limestone or clay. Lime and clay make VCT very porous and thus highly absorbent. Without the protective coating of floor wax as a sealer, dirt, grease, and grime will get pressed down into the structure of the tile. The discoloration is not just unsightly; some substances will damage or destroy the tile itself or the adhesive holding it in place. The damage is permanent and the tiles must be replaced.

Unfortunately, due to foot traffic, floor wax and finishes eventually wear away.

Now lets introduce floor care and maintenance for VCT

Strip and wax versus top scrub and recoat

When it comes to hard floor care and maintenance, knowing when to strip and wax as opposed to scrub and recoat can save your business time and money.

Stripping and waxing a floor is labor-intensive, requires several additional steps not required when scrubbing and recoating, uses additional chemicals, is more prone to mistakes and damage when performed by inexperienced service providers, and maybe entirely unnecessary for your hard floors' needs.

Conversely, scrubbing and recoating is generally a two-step process that can be completed quickly, and leaves relatively little opening for floor damage when performed by an experienced service provider.

Regardless of cost, and depending on your facility's floor care requirements, one type of service is likely a superior option to the other.

When to strip and wax

Stripping a hard floor requires the complete removal of all layers of floor coating and sealant, and is most commonly employed when there is a significant buildup of dirt and gunk around the edges.

The process involves the application of a harsh scrubbing chemical applied with an aggressive scrubbing pad.

Once the floor is completely stripped, a neutralizer must be applied to remove any remaining wax residue, which can result in a subpar finish and require the job to be completely redone.

Before applying the wax finish, a sealant must be applied to the floor--offering a layer of additional protection.

Next, the wax coating is applied in layers.

After each application, the service provider must wait for the solution to completely dry before re-entering to apply an additional layer.

Finally, a buffer is used to bring the floor to a shine.

When to scrub and recoat

Scrubbing and recoating is performed when there is little to no finish remaining on the floor, or there is no buildup requiring a full strip and wax.

The process is much faster--requiring the removal of the top layer(s), or remaining layer of wax, and uses fewer and less harsh chemicals and a much less aggressive scrubbing pad.

The scrubbing process removes any deeply embedded soils from the floor and prepares it for reapplication of floor finish.

Advancements in floor preparation equipment have made the process of scrub and recoat safer and faster through the use of orbital machines that allow facilities to tackle their projects chemically free, significantly reduce labor costs, and increase facility safety.

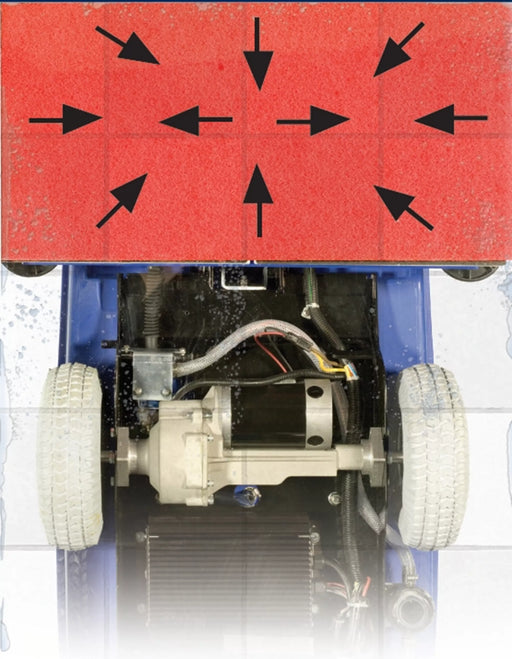

Orbital Automatic Scrubbers use a micro-orbital motion to provide their mechanical cleaning interaction with the floor. The total motion is only about ¼ of an inch, but the speed (in RPM) is approximately 10-12 times that of a traditional disk auto scrubber. This allows for delivery of much more mechanical cleaning action to the floor in a uniform manner across the entire cleaning pad, for superior cleaning in a much shorter time period.

Five Questions to Consider When Choosing an Orbital Floor Cleaning Machine:

- Is the machine built durably enough for daily use in a wide variety of tasks?

- Does the machine have good vibration mitigation to allow operators comfortable use for a long period of time?

- Is the machine maneuverable enough to work in corners and along edges, saving operator time and effort?

- Is the machine effective in a range of tasks, from cleaning lightly soiled floors to stripping multiple coats of floor finish?

- If sustainability is a consideration, does the machine provide the option of cleaning or stripping floors without added chemicals?

While orbital floor scrubbing machines may have originally been built only for special projects, the current reality is different. Consider them as multipurpose floor cleaning machines that can handle almost any type of flooring issue – regular daily scrubbing, project use, deep cleaning, and more.

-

Clarke CA60, Floor Scrubber, 20" or 24", 16 Gallon, Battery, Self Propel, Disk or Orbital

No reviewsOriginal price $0.00 - Original price $0.00Original price$7,138.00 - $10,102.00$7,138.00 - $10,102.00Current price $7,138.00| /Original price $0.00 - Original price $0.00Original price$7,138.00 - $10,102.00$7,138.00 - $10,102.00Current price $7,138.00| / -

Clarke Focus II, Floor Scrubber, 28", 32", 23 Gallon, Battery, Self Propel, Boost (Orbital)

No reviewsOriginal price $0.00 - Original price $0.00Original price$14,459.00 - $19,195.00$14,459.00 - $19,195.00Current price $14,459.00| /Original price $0.00 - Original price $0.00Original price$14,459.00 - $19,195.00$14,459.00 - $19,195.00Current price $14,459.00| /